ERP Systems With Advanced Production Scheduling: Complete Guide, Features and Details

Implementing an Enterprise Resource Planning (ERP) system is a significant undertaking for any manufacturing business. I’ve been through the trenches, both as a consultant and as a project manager, overseeing ERP implementations for companies ranging from small job shops to multi-national corporations. One of the biggest differentiators between a successful ERP implementation and one that falls flat is the effective integration of advanced production scheduling. It’s not enough to just track inventory and financials; you need a system that can truly optimize your production processes.

Too often, companies underestimate the complexity of production scheduling and try to shoehorn it into a basic ERP module. This leads to reliance on spreadsheets, manual calculations, and constant fire-fighting. The result? Missed deadlines, wasted resources, and frustrated employees. A well-chosen ERP system with advanced production scheduling capabilities can transform your manufacturing operations, providing real-time visibility, improved efficiency, and a competitive edge.

This guide will explore the critical features of ERP systems with advanced production scheduling, common challenges in implementation, and how to choose the right solution for your specific needs. We’ll delve into the functionalities that separate a good system from a great one, and offer practical advice based on real-world experiences. This isn’t just about theory; it’s about providing you with the knowledge you need to make informed decisions and successfully implement an ERP system that will drive your business forward.

What is an ERP System with Advanced Production Scheduling?

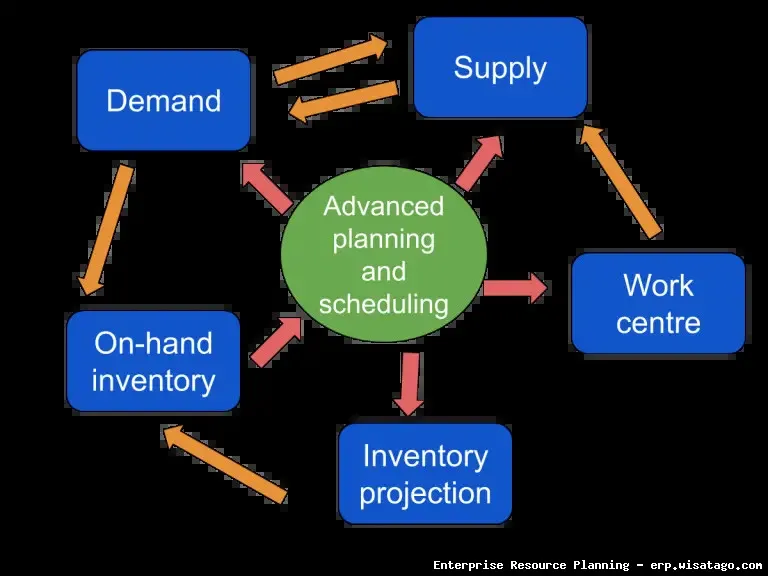

At its core, an ERP system integrates all facets of a business, including planning, manufacturing, sales, marketing, finance, human resources, and more. When we talk about “advanced production scheduling,” we’re referring to a sophisticated module within the ERP system that goes beyond basic capacity planning. It uses algorithms and data-driven insights to optimize the production schedule, taking into account constraints like machine availability, material availability, labor skills, and due dates.

Key Features of Advanced Production Scheduling

Here are some essential features to look for in an ERP system with advanced production scheduling:

- Finite Capacity Scheduling: This is crucial. Unlike infinite capacity scheduling, which assumes unlimited resources, finite capacity scheduling recognizes that resources are limited and allocates them accordingly. It prevents overloads and accurately predicts bottlenecks.

- Material Requirements Planning (MRP): A solid MRP module is the backbone of any production scheduling system. It ensures that the right materials are available at the right time to meet production demands.

- Constraint-Based Scheduling: Identifies and addresses the constraints that are limiting production output. This could be a specific machine, a skilled worker, or a raw material shortage.

- Drag-and-Drop Scheduling: Provides a visual interface that allows schedulers to easily adjust the production schedule by dragging and dropping operations. This offers flexibility and responsiveness to changing conditions.

- What-If Scenario Planning: Enables users to simulate different scenarios (e.g., a machine breakdown, a rush order) and assess the impact on the production schedule. This allows for proactive decision-making and contingency planning.

- Real-Time Visibility: Provides real-time updates on the status of orders, machine performance, and material availability. This enables quick identification and resolution of issues.

- Integration with Shop Floor Control: Seamlessly integrates with shop floor data collection systems to track actual production progress and identify deviations from the schedule.

- Optimization Algorithms: Uses algorithms to optimize the production schedule based on various objectives, such as minimizing lead times, maximizing throughput, or reducing inventory levels.

- Reporting and Analytics: Provides comprehensive reports and analytics on production performance, including capacity utilization, on-time delivery, and resource efficiency.

Benefits of Implementing ERP with Advanced Production Scheduling

The benefits of implementing an ERP system with advanced production scheduling can be substantial. Here’s a breakdown of some key advantages:

Improved Efficiency and Productivity

By optimizing the production schedule, businesses can significantly improve efficiency and productivity. Advanced scheduling algorithms can minimize idle time, reduce changeover times, and maximize machine utilization. This translates to higher output with the same resources.

Reduced Lead Times

Advanced scheduling helps to streamline the production process and minimize delays. By accurately forecasting material requirements and optimizing resource allocation, businesses can significantly reduce lead times and deliver products to customers faster.

Lower Inventory Levels

With better visibility into production demands and material availability, businesses can reduce inventory levels and minimize carrying costs. Advanced scheduling enables just-in-time (JIT) inventory management, ensuring that materials are only ordered when needed.

Increased On-Time Delivery

Accurate scheduling and real-time visibility into production progress enable businesses to improve on-time delivery performance. This leads to increased customer satisfaction and stronger customer relationships.

Better Resource Utilization

Advanced scheduling helps to optimize the utilization of all resources, including machines, labor, and materials. This ensures that resources are used efficiently and effectively, minimizing waste and maximizing return on investment.

Improved Decision-Making

Real-time data and comprehensive reports provide decision-makers with the information they need to make informed decisions. This enables proactive problem-solving and continuous improvement.

Common Challenges During Implementation

Implementing an ERP system with advanced production scheduling is a complex project, and there are several common challenges that businesses need to be aware of:

Data Migration and Cleansing

Migrating data from legacy systems to the new ERP system can be a daunting task. Data cleansing is essential to ensure that the data is accurate, consistent, and complete. This process can be time-consuming and requires careful planning.

Resistance to Change

Implementing a new ERP system often requires significant changes to business processes and workflows. Employees may resist these changes, especially if they are not adequately trained and supported. Effective change management is crucial for successful implementation.

Lack of User Training

Proper user training is essential to ensure that employees can effectively use the new ERP system. Insufficient training can lead to errors, inefficiencies, and frustration. Training should be tailored to the specific roles and responsibilities of each user.

Inadequate Planning

Inadequate planning is a common cause of ERP implementation failures. Businesses need to carefully define their requirements, develop a detailed project plan, and allocate sufficient resources to the project. A phased approach to implementation is often recommended.

Poor Communication

Poor communication between the implementation team, the ERP vendor, and the end-users can lead to misunderstandings and delays. Regular communication and collaboration are essential for successful implementation.

Scope Creep

Scope creep, or the gradual addition of new features and requirements during the implementation process, can lead to budget overruns and delays. It’s important to carefully manage the scope of the project and avoid adding unnecessary features.

Choosing the Right ERP System

Selecting the right ERP system with advanced production scheduling is a critical decision. Here are some key factors to consider:

Assess Your Business Needs

Start by carefully assessing your business needs and requirements. What are your pain points? What are your goals? What specific features do you need in an ERP system? Documenting these requirements will help you narrow down your options.

Evaluate Different Vendors

Research and evaluate different ERP vendors. Look for vendors with a proven track record of successful implementations in your industry. Consider factors such as functionality, scalability, cost, and vendor support.

Request Demonstrations

Request demonstrations from potential vendors. This will give you a chance to see the ERP system in action and assess its usability. Be sure to ask specific questions about the features and functionalities that are important to your business.

Check References

Ask vendors for references from other customers in your industry. Contact these references and ask about their experience with the ERP system and the vendor.

Consider Cloud vs. On-Premise

Decide whether you want a cloud-based ERP system or an on-premise system. Cloud-based systems are typically less expensive to implement and maintain, but they may not offer the same level of customization as on-premise systems.

Evaluate Integration Capabilities

Ensure that the ERP system can seamlessly integrate with your existing systems, such as CRM, PLM, and accounting software. Integration is essential for ensuring data consistency and streamlining business processes.

. For more information, you can refer to ERP as an additional resource.

Think About Scalability

Choose an ERP system that can scale with your business as it grows. The system should be able to handle increasing transaction volumes and accommodate new users and features.

Consider the Total Cost of Ownership

Consider the total cost of ownership (TCO) of the ERP system, including implementation costs, maintenance costs, and training costs. Don’t just focus on the initial purchase price; factor in the long-term costs of owning and operating the system.

Lessons Learned From Real-World Implementations

Having been involved in numerous ERP implementations, I’ve learned a few key lessons that I’d like to share:

Get Executive Buy-In

Executive buy-in is essential for successful ERP implementation. Without the support of senior management, the project is likely to face resistance and lack of resources.

Form a Dedicated Implementation Team

Form a dedicated implementation team with representatives from all key departments. This team should be responsible for planning, executing, and monitoring the implementation project.

Don’t Underestimate the Importance of Training

Invest in comprehensive user training. Ensure that all users are properly trained on the new ERP system before it goes live. Provide ongoing support and training as needed.

Start Small and Iterate

Consider a phased approach to implementation. Start with a limited scope and gradually add new features and functionalities. This will help to minimize risk and ensure that the system is properly configured before it is rolled out to the entire organization.

Monitor Performance and Make Adjustments

Continuously monitor the performance of the ERP system and make adjustments as needed. This will help to ensure that the system is meeting your business needs and delivering the expected benefits.

In conclusion, implementing an ERP system with advanced production scheduling can be a transformative experience for manufacturing businesses. By carefully planning the implementation, choosing the right system, and addressing common challenges, you can unlock significant benefits in terms of efficiency, productivity, and profitability. Remember, it’s a journey, not a sprint. Take the time to do it right, and the rewards will be well worth the effort.

Conclusion

In conclusion, the integration of advanced production scheduling within ERP systems represents a significant leap forward for manufacturing organizations. By leveraging sophisticated algorithms and real-time data, these systems optimize resource allocation, minimize bottlenecks, and ultimately drive greater efficiency and profitability. The ability to dynamically adjust schedules in response to unforeseen events, coupled with improved visibility across the entire supply chain, positions businesses to be more agile and competitive in today’s rapidly evolving market.

This article has highlighted the key benefits and functionalities of these advanced ERP systems. As businesses strive for operational excellence and seek to optimize their production processes, investing in an ERP system with robust production scheduling capabilities is no longer a luxury, but a necessity. If you’re ready to transform your manufacturing operations and gain a competitive edge, we encourage you to explore the leading ERP solutions available and discover how they can be tailored to meet your specific needs. Consider researching case studies and contacting vendors for personalized demonstrations to determine the best fit for your organization. The future of manufacturing is efficient, data-driven, and strategically scheduled; are you ready to embrace it?

Frequently Asked Questions (FAQ) about ERP Systems with Advanced Production Scheduling

What are the key benefits of integrating Advanced Production Scheduling (APS) within an ERP system for manufacturing companies?

Integrating Advanced Production Scheduling (APS) within an ERP system offers numerous benefits for manufacturing companies. Firstly, it significantly improves production efficiency by optimizing resource allocation, minimizing bottlenecks, and reducing lead times. APS algorithms consider various constraints such as machine capacity, material availability, and labor skills to create realistic and achievable production schedules. Secondly, integrating APS with ERP enhances visibility across the entire supply chain. By connecting production schedules with sales orders, inventory levels, and procurement plans, companies can proactively respond to changing customer demands and avoid stockouts. Finally, APS integration leads to improved on-time delivery performance. By accurately predicting completion dates and proactively addressing potential delays, companies can enhance customer satisfaction and build stronger relationships.

How does an ERP system with Advanced Production Scheduling help reduce material waste and inventory costs in a manufacturing environment?

An ERP system with Advanced Production Scheduling (APS) plays a crucial role in reducing material waste and minimizing inventory costs. APS optimizes production schedules by accurately forecasting demand and aligning production with actual customer orders. This prevents overproduction, thereby reducing the risk of obsolete inventory and associated waste. Furthermore, APS considers material constraints and lead times when creating schedules, ensuring that materials are available when needed, minimizing excess inventory holding costs. By leveraging real-time data on inventory levels and production progress, APS within an ERP enables better material planning and procurement decisions. This leads to reduced material waste, lower inventory carrying costs, and improved overall operational efficiency. The system helps to implement Just-In-Time (JIT) inventory management, reducing the need for large safety stocks.

What are the key features to look for when choosing an ERP system with Advanced Production Scheduling capabilities for a discrete manufacturing business?

When selecting an ERP system with Advanced Production Scheduling (APS) for a discrete manufacturing business, several key features should be considered. First, look for robust scheduling algorithms that can handle complex manufacturing processes, including finite capacity scheduling, constraint-based scheduling, and multi-level BOM planning. The system should support various scheduling methods like forward scheduling and backward scheduling. Second, consider the system’s ability to integrate with other ERP modules, such as inventory management, sales order processing, and shop floor control, for real-time data exchange. Third, ensure the APS offers strong visualization capabilities, allowing users to easily view and modify schedules through interactive Gantt charts and other graphical interfaces. Finally, evaluate the system’s reporting and analytics capabilities to track key performance indicators (KPIs) such as on-time delivery, resource utilization, and production costs. A flexible and customizable system is essential to adapt to specific business needs and evolving requirements.